Film Extrusion

Worthen Film Extrusion Capabilities

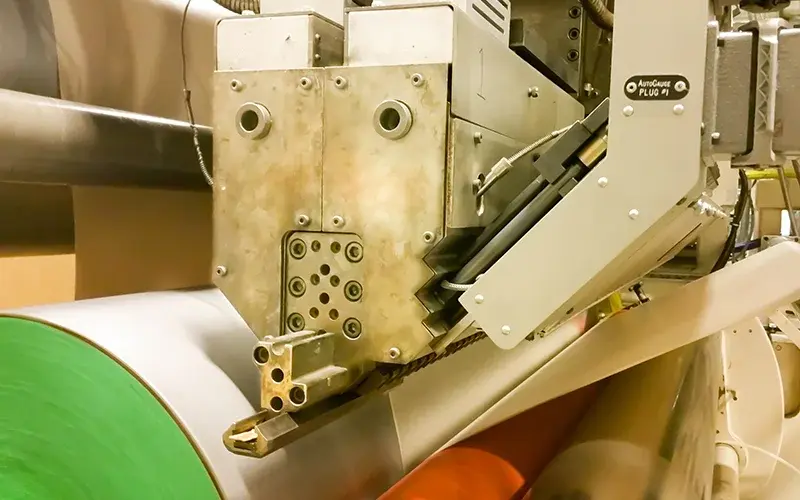

Worthen Industries extrudes thermoplastic resins for supported or unsupported film products. Our strong technical team can custom-develop thermoplastic compounds and blends to suit most applications. Our processing versatility allows us to convert most thermoplastic materials as a film or laminate structure to paper, film, or fabric. Our in-house development capabilities allow us to create film properties for the most demanding physical, environmental, and post-processing applications.

Processing locations: both Nashua, NH facilities

Processing

Capabilities

Our basic film construction capabilities are as follows, but we encourage you speak to our customer service representatives about our full range of capabilities:

Gauge - 0.001 - 0.015 inches

Width - 40 – 72 inches

Multi-layering capabilities

Package size from 50 to 2000 linear yds – 40 inch diameter (dependent on web gauge)

Worthen Thermoplastic Materials Capabilities

Our range is High Molecular weight structural grades to Low Molecular weight elastomers and thermal activated adhesives systems. Olefins - Polyethylene, Polypropylene and Copolymers TPU – Thermoplastic Urethane – Polyester and Polyether Copolyesters with softening point temperatures as low as 65°C TPR – TPV's - EPDM based elastomers. All of these material can be custom blended or compounded with additive systems for physical reinforcement, flame retardance, UV resistance, color, adhesion promotion, antiblock and other required properties

Industry News

.png?width=175&height=87&name=worthen_logo%202023%20FINAL%20(6).png)