Laminating Adhesives & Coatings

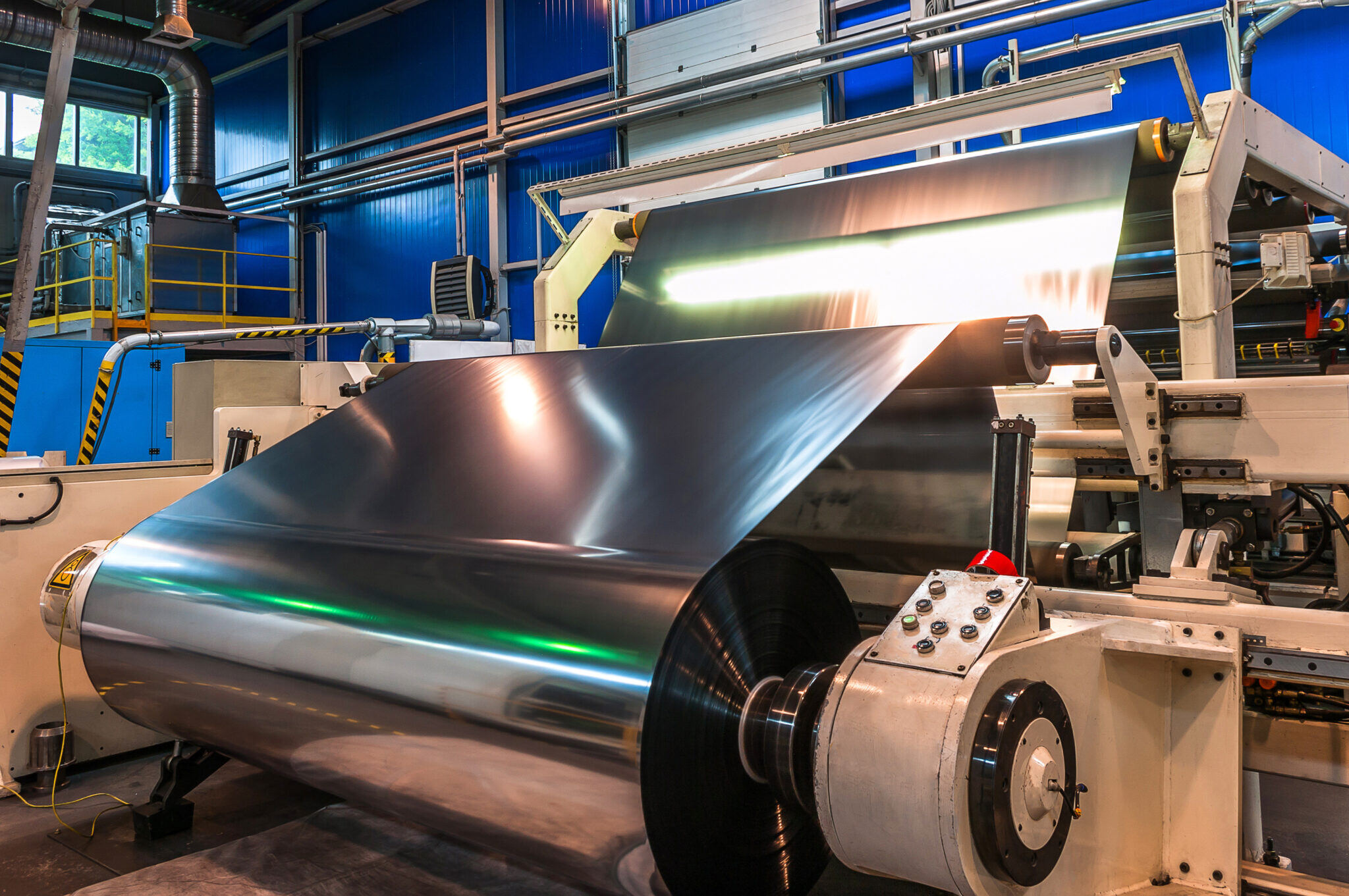

LAMINATING ADHESIVES & COATINGS

Worthen Industries manufactures a wide range of solvent based, water based and solventless laminating adhesives. Chemistries include, but not limited to, polyester (medium and high molecular weight) and urethane technologies to meet a various performance characteristics. These adhesives are formulated for many industrial, aerospace, medical and flexible packaging applications and bond to many different substrates such as paper, fabrics (woven and nonwoven), foils and various films. They can be supplied as clear, pigmented and with fire retardant loading.

HEAT SEAL COATINGS

Worthen Industries provides heat seal technology that is formulated to meet specific application requirements. These coatings are formulated to meet various heat seal temperatures and dwell times. Applications include heat seals for industrial use, lidding films and electronic packaging.

PRIMERS AND TOP COATS

Worthen Industries products include adhesion promoters, ink receptive primers and various top coats that impart print protection, as well as abrasion, chemical, water and UV resistance. Whether you need a water based or solvent product, Worthen can develop a system to meet the various performance properties you require.

Laminating Adhesives & Coatings Contact Form

Form Name

Industry News

.png?width=175&height=87&name=worthen_logo%202023%20FINAL%20(6).png)